- Building Acoustics

- Industrial Noise

- Vibration in Buildings

- Vibration in Pipework

- Planning, Permitting & Sustainability

- Pulsation Analysis

- Surge Analysis

- Measurement & Testing

- Services to Consultants

Case Studies: Noise Control Design

Petroplus Refinery, Coryton UK – Boiler Acoustic Resonance

TEI commissioned Spectrum to study an unusual acoustic resonance on a 70 tonne/hr waste heat boiler which was so severe the boiler’s output had to be throttled back significantly. Spectrum undertook site measurements, evaluated the boiler internal dimensions and gas flow conditions before concluding that vortex shedding frequencies from the tube bundle coincided with cross boiler eigenvalues. Spectrum designed a series of steel baffle plates which once installed solved the problem completely, and allowed full operation of the boiler again.

ExCel Exhibition Centre, London – Very Large Acoustic Doors

Specialist door manufacturer, Jewers, commissioned Spectrum to undertake the acoustic design for 4 Esavian® doors at the prestigious ExCel Exhibition and Conference Centre in London. The Centre is located close to London City Airport. Each door had to achieve a field rating level of R’w >45dB. Working with Jewers Engineering Department, the door skin system was established based around a strong steel frame to ensure rigidity and alignment in operation. Seals were pneumatic fed by compressors built into the door panel. Tests in situ showed the doors fully met the specification.

ConocoPhillips Oil Terminal, Teeside, UK

Following the operational failure of a Vapour Recovery Unit at ConnocoPhillips Teeside crude oil terminal, Spectrum monitored and assessed noise and vibration of the unit against guideline acceptability levels and advised on possible noise and vibration control measures. Noise measurements were taken close to the equipment and also at potential future office locations for input into design models. Vibration measurements were taken on both the machines and also the support structure in order to assess the effects of start-up and continuous operation on vibration levels.

Rio Tinto Alcan 70MW Lochaber Hydroelectric Power Station, Scotland

Spectrum measured and evaluated the noise from hydro turbines at this well-established power plant providing clean renewable energy to the nearby aluminium plant. Noise control designs were developed for silencing the generator cooling systems and noise radiating from the hydro turbine casings. Spectrum supervised the installation of noise control and established noise levels reduced by in excess of 10dBA throughout the power station. Spectrum have undertaken a large number of similar projects mainly in Scotland for SSE.

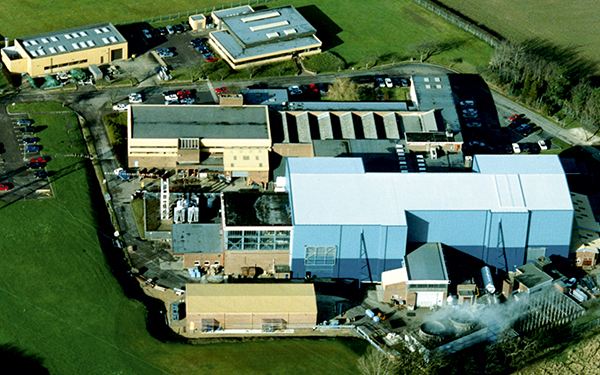

Aircraft Research Association, TWT Acoustic Building, Bedford, UK

ARA’s well known transonic wind tunnel with its huge 28MW powered fan was built in 1954 and is thought to have been used in aerodynamically testing over 50% of the western world’s military aircraft. As part of environmental improvements to the site, Spectrum was invited to prepare design options for noise control of the facility. ARA then asked Spectrum to detail design and supervise the construction of a large high performance acoustic building to completely enclose the wind tunnel, along with ancillary noise control systems for compressors and cooling towers. This is shown in the photograph as the main blue building. Tests showed it effective in reducing noise at housing from 58 dB(A) to 38 dB(A)