- Building Acoustics

- Industrial Noise

- Vibration in Buildings

- Vibration in Pipework

- Planning, Permitting & Sustainability

- Pulsation Analysis

- Surge Analysis

- Measurement & Testing

- Services to Consultants

Road tanker loading line jumps off supports on start-up due to pressure surge from vapour cavity collapse

28 November 2019 by Martin Hamilton, Principal Consultant

This project provides a typical example of how Surge Analysis can be used to solve a potentially dangerous problem on a Petrochemical Plant.

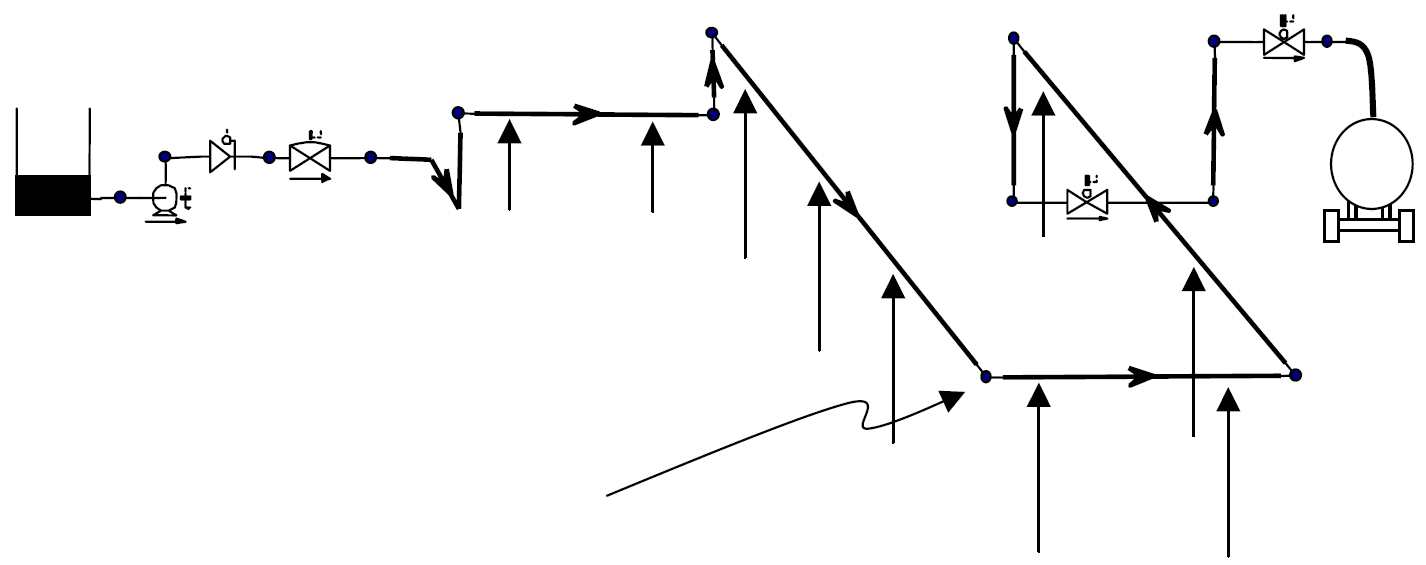

A 6” Sulphuric Acid road tanker loading line was located several hundred metres in length from the storage tank, passing over pipe racks to the tanker loading bay.

Tanker Loading Line Schematic

Concern was raised when operators would sometimes hear a large bang on start-up of the pump to load a road tanker, and the line sometimes jumped and fell off its supports.

Water hammer (or in this case sulphuric acid hammer) was suspected. However, rather than address the root cause generating the forces causing the line displacement, the operator tried to address the symptoms by installing additional guides and line-stops and replacing the pump discharge check valve.

Initial attempts by the operator to mitigate the surge problem had failed

Unfortunately these measures didn’t work and the operator also suffered an expensive canned pump failure.

Analysis by Spectrum Fluid Dynamics showed that the operator was expecting a check valve to provide a positive isolation between batches, however this was not reasonable and did not work. When storage tank levels were low, a slow reverse flow from the pipe-rack back to the storage tank occurred between batches, leaving vapour cavities in the line.

Subsequent vapour cavity collapse on start-up with no back pressure on the pump could generate transient pressures up to 40 barg and out-of-balance forces of up to 10 tonnes.

The solution, after discussion between Spectrum and the operator, was to incorporate a positive isolation valve at pump discharge which would shut as part of the control logic for the batch loading operations, keeping the line hydraulically full until the start of the next loading operation.

Following the implementation of Spectrum’s recommendations, no recurrences of the bangs and jumping line were reported.