- Building Acoustics

- Industrial Noise

- Vibration in Buildings

- Vibration in Pipework

- Planning, Permitting & Sustainability

- Pulsation Analysis

- Surge Analysis

- Measurement & Testing

- Services to Consultants

Spectrum provides services from initial noise predictions to noise Factory Acceptance Tests (FAT) for equipment suppliers on offshore platform projects

25 January 2017 by Chris Anderson, Director

Spectrum Acoustic Consultants Ltd provides services from initial noise predictions through to noise factory acceptance tests (FAT) for equipment suppliers. Spectrum also witnesses noise FAT tests on behalf of EPC contractors in order to ensure the tests are undertaken in line with the applicable test procedures.

Equipment Noise Data Sheets

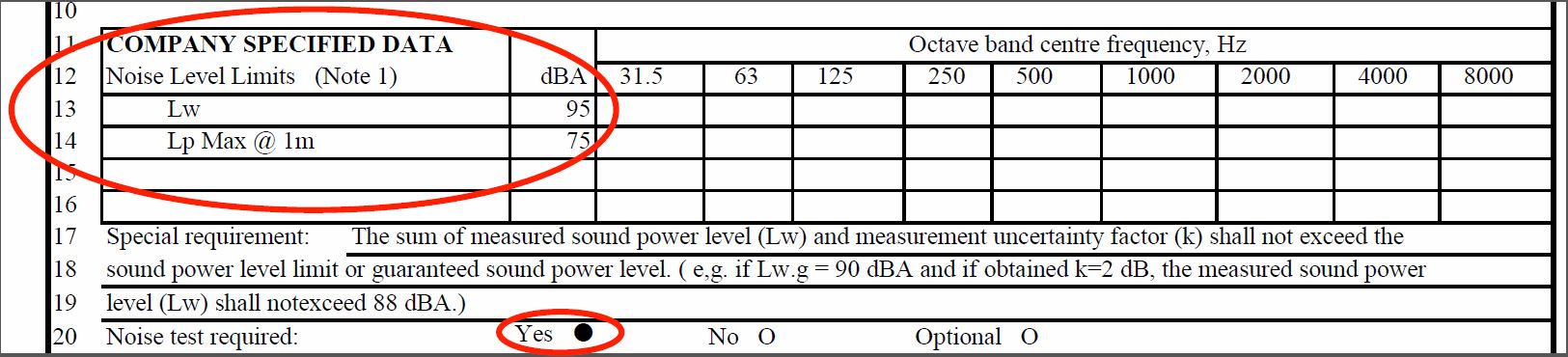

Noise data sheets for offshore equipment typically specify equipment noise limits (Company specified data) and require the vendor to provide initial noise guarantees (supplier data) and final measured noise levels (as built noise data).

Company Specified Data

Early in the project, the EPC contractor will typically issue a noise data sheet specifying a noise limit as shown in the example below. This data sheet indicates that a noise test will be required and this will typically be undertaken as part of the factory acceptance test (FAT) schedule, shortly before transportation of the equipment to the shipyard.

Part of an Equipment Noise Data Sheet showing noise limits

Supplier Data

Since the FAT noise test may be a year or more after the equipment in purchased, the project will generally require either indicative or guaranteed equipment noise data well before this in order that the overall noise level on the platform can be predicted. Hence, if the equipment is non-standard or has not been tested before, Spectrum may be asked to undertake noise predictions on behalf of the supplier using known or estimated noise data for the equipment components. This enables the supplier data to be provided along with a report on how the calculations were undertaken. The project can then use this data to make preliminary noise predictions on the platform.

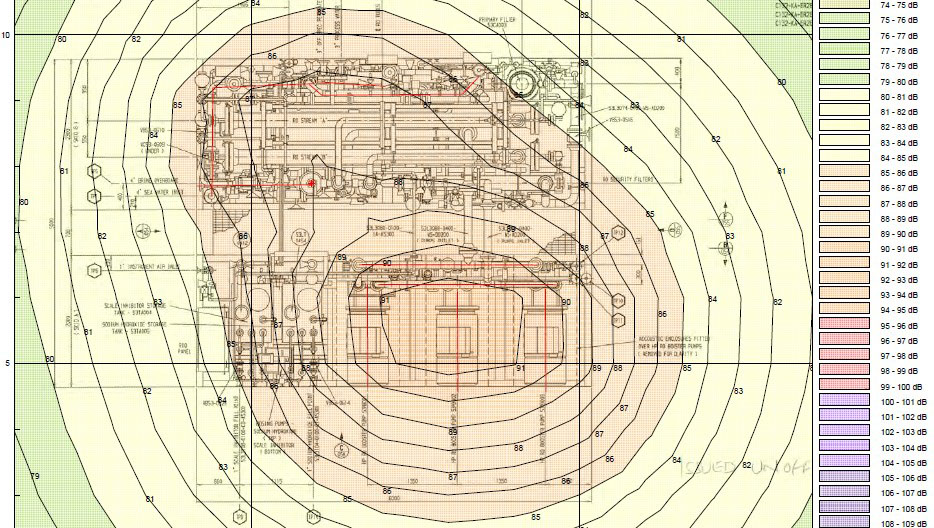

Noise Model of a water maker for an offshore platform

Part of an Equipment Noise Data Sheet showing supplier noise data

As Built Noise Data

When manufacturing and performance testing is complete, a noise factory acceptance test (FAT) will typically be undertaken at the supplier’s factory. The ideal noise test environment would be under free-field (out-door) conditions, with no reflecting surfaces other than the ground and no significant background noise. Unfortunately, however, these conditions are generally impractical to achieve and noise FAT testing is usually undertaken indoors at the equipment supplier’s factory. Here, the acoustic conditions are likely to be unfavourable due to the highly reverberant sound field inside a typical industrial building, along with the possibility of significant background noise levels due to extraneous noise sources such test loop pressure let-down valves or electrical generators.

Noise Factory Acceptance Tests (FAT) are typically undertaken

in an unfavourable acoustic environment

In view of the above, Spectrum uses sound intensity for noise factory acceptance tests to ISO BS EN ISO 9614-2:1997 Acoustics – Determination of sound power levels of noise sources using sound intensity – Part 2: Measurement by scanning where possible. This is because it is generally accepted that sound intensity measurement leads to improved measurement accuracy and therefore lower uncertainty in the measured data. Indeed, Spectrum understands that future projects may insist on the use of sound intensity for noise FAT for these reasons.

With the noise FAT measurements complete, Spectrum can report to the equipment supplier the appropriate values to be included on the as built section of the equipment noise data sheet so that this can be submitted to the EPC contractor so that the equipment can be transported to the shipyard and installed on the platform.

Completed as-built noise data following a noise FAT for submission to the project

More information on Factory Acceptance Tests [FAT]